Rail Safety Begins With The Wheelset Press

Throughout the railway industry, safety is the highest priority. The Association of American Railroads (AAR) and the Federal Railroad Administration (FRA) set clear standards for wheel and axle integrity across freight, locomotive, and passenger rail. Even something as simple as a misaligned coupling can result in dangerous derailment events. As such, the FRA and AAR mandate that all wheelset assemblies have documented validation proving their compliance with strict dimensional and performance thresholds designed to prevent critical failures.

As federal safety standards grow more exacting and oversight more precise, the machinery behind wheelset assembly has taken on new importance. The safety of any rail vehicle depends on the integrity of its wheelset, including precision alignment, crack-free press zones, and component symmetry. With mounting pressure to ensure component fit, structural integrity, and traceability, rail operators, maintenance, repair, and overhaul (MRO) facilities, and OEMs are turning to advanced wheelset press technology to ensure compliance.

Innovations in Wheelset Press Technologies

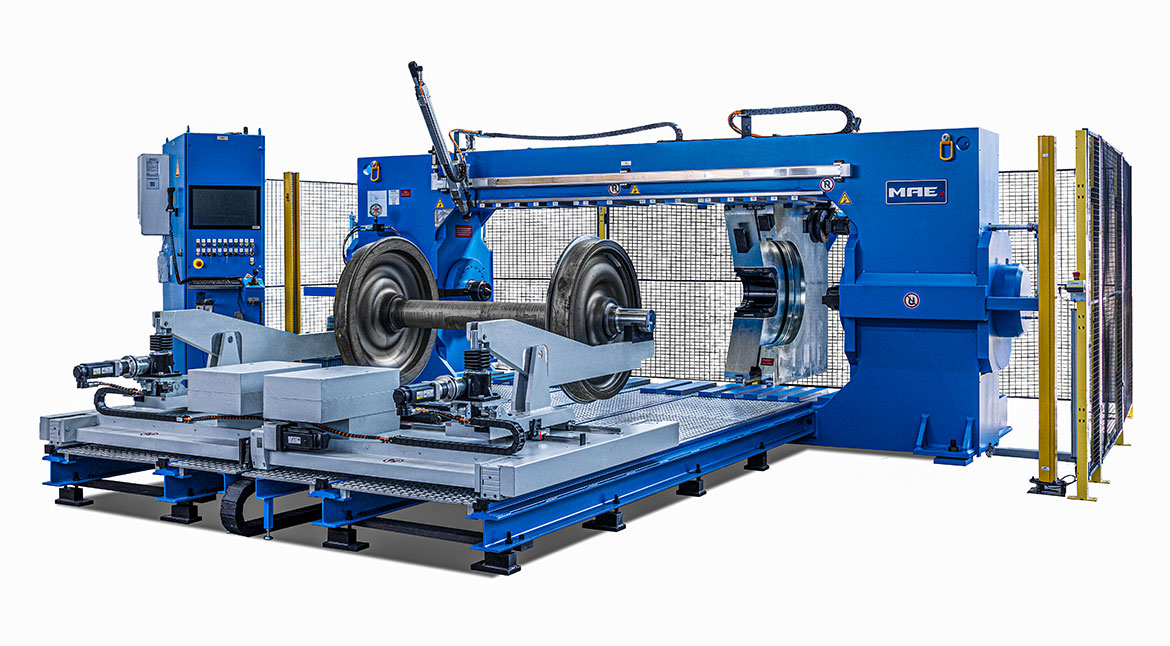

Today’s most advanced wheelset presses utilize servo-controlled hydraulics, real-time force monitoring, and digital press profile validation to ensure every component meets exacting standards. From real-time force monitoring and anomaly detection to adaptive controls, the newest innovations in wheelset press technologies all align to reduce operator risk, eliminate rework, and ensure every assembly meets regulatory guidelines.

Fully Automated Pressing with Real-Time Monitoring

Automated control systems with live force and displacement monitoring validate each press fit as it occurs, using adaptive controls and programmable press routines to accommodate a wide range of specifications. MAE-Eitel’s cutting-edge automated wheelset presses take human error out of the equation, minimizing variability to ensure the reliable consistency needed for modern rail requirements.

Digital Traceability and Data Logging

Advanced wheelset presses harness the connectivity of IoT technology to provide instant production insights with digital process logging that ensures full traceability and audit readiness. Each pressing operation is automatically recorded, giving operators, inspectors, and regulators a verified digital history of every wheelset assembled, simplifying compliance with AAR documentation standards.

Automatic Defect Detection

Real-time feedback loops and digital force curve monitoring enable advanced anomaly detection mid-process. When an interference fit deviates from expected parameters, whether due to improper alignment, bore variance, axle damage, or thermal expansion, the system flags the event before the assembly moves forward. These cutting-edge diagnostic capabilities facilitate rapid issue correction, preventing costly problems downstream.

Inspection and Testing Integration

Integrated measurement and geometry validation tools verify axial runout, offset, and press-fit depth without interrupting workflow. Highly sophisticated sensors ensure each wheelset meets exact specifications, giving operators the confidence that each assembly meets tolerance expectations.

From Performance to Process Optimization

While automation and digital feedback transform what a wheelset press can do, long-term safety and compliance also depend on how well the equipment is integrated into the broader manufacturing process. MAE-Eitel not only builds industry-leading wheelset presses but also helps rail operators, MROs, and OEMs maximize the performance of their existing infrastructure through targeted optimization and retrofitting.

Maximizing Performance

Process optimization includes fine-tuning press parameters, improving pressing routines, and streamlining workflows for safer, faster, and more consistent operation. Whether reducing cycle time or aligning equipment performance with new FRA standards, MAE-Eitel’s optimization services lower risks and increase system reliability over the long haul.

Retrofitting Legacy Equipment

Retrofitting legacy equipment with the newest advancements in wheelset press technology allows facilities operating older mechanical or hydraulic systems to upgrade performance capabilities without investing in complete system replacement. MAE-Eitel retrofits, which can include hydraulic system upgrades, control systems, and digital monitoring tools, give older machines the same level of precision and reliability as newer builds.

Staying Ahead of the Curve With Advanced Wheelset Presses

In today’s safety-focused rail industry, saying you produce precision assemblies alone isn’t enough to meet regulatory requirements. To ensure FRA and AAR compliance and long-term rail safety, manufacturers and operators need technologies that elevate the entire assembly process and provide the documentation that proves it. MAE-Eitel’s custom wheelset presses, process optimization services, and retrofit capabilities give rail operators the tools they need to stay in compliance and meet tomorrow’s challenges.

Ready to discover what innovation can do for your wheelset operations? Talk to MAE-Eitel about high-performance wheelset assembly solutions engineered for safety, precision, and long-term reliability.